Northmen Home

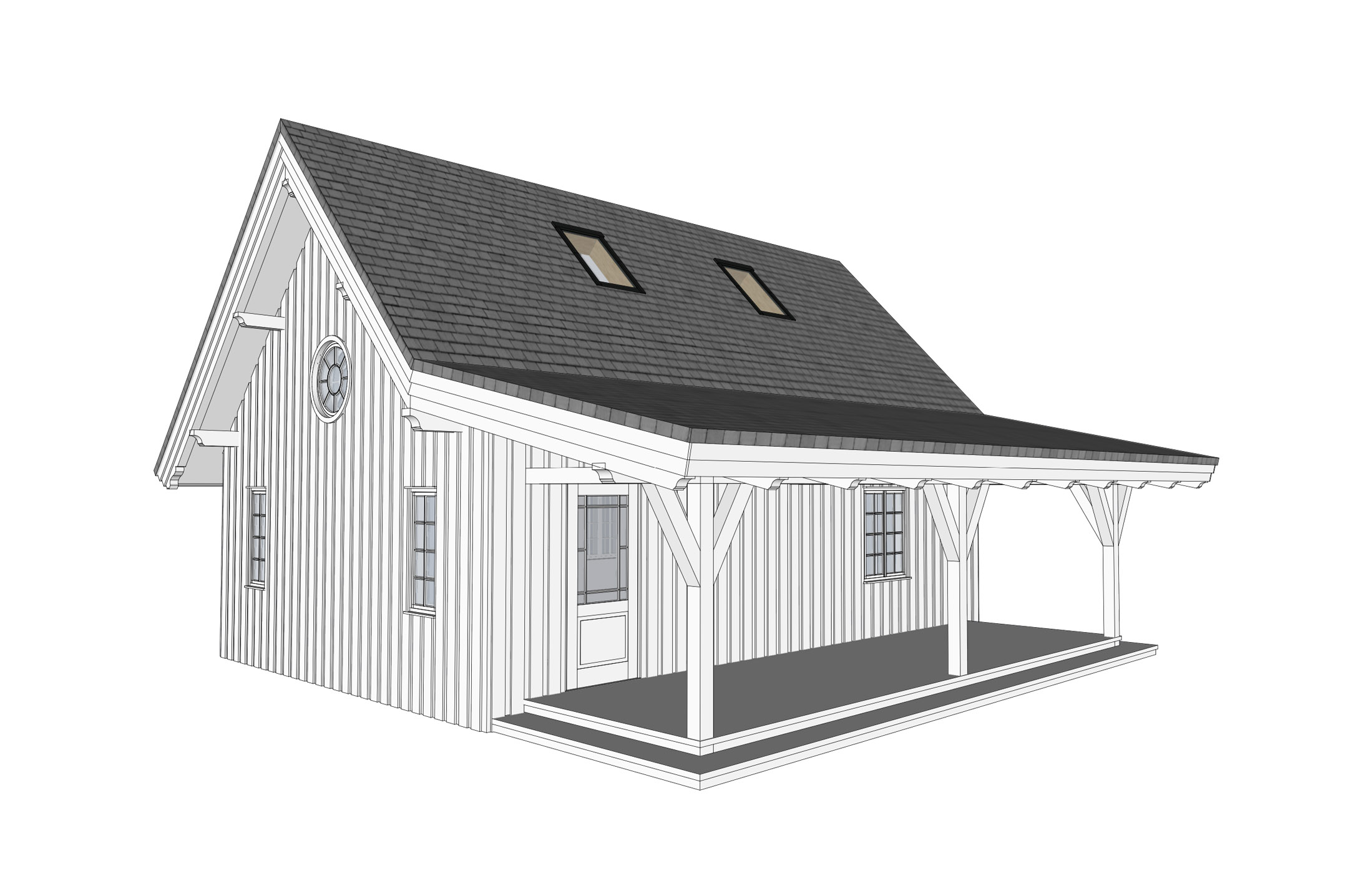

Designed, engineered and crafted by our master carpenters, the Northmen wooden home is built as a massive timber frame house with time tested mortise and tenon joinery locked with white oak pegs. In the house making process we use only massive single piece timbers harvested by a lunar calendar not using any modern glued beams or boards. The house is built only from natural materials - wood, clay, stone, bricks and lime. All the wood shavings from building process - planing boards and timbers - are used into the wall insulation blocks.

In the modern building industry nobody cares how all the plastic, foam, Rockwool or fibreglass wool materials will naturally decompose, because nobody knows how many hundreds of years it will it take. By building our house we know that all the materials used in our build will naturally decompose and turn into soil in few decades when the house is broken down.

The characteristics of the Northmen houses are:

- Zero waste

- Zero concrete

- Zero plastic and rubber

- Zero modern toxic glues

- Zero chemical paints

- Zero allergens

- Very low maintenance

- Hurricane resistant

- 4 meters of roof snow load resistance (for northern climate)

- Extra strong traditional joinery

- Earthquake resistant up to 8.0 magnitude on Richter scale.

- Low energy consumption and heating costs

- 100% made of natural and eco-friendly materials

Winter moon wood

Austrian wood engineer and forester Mr. Ervin Thoma has scientifically proven based on his research that wood has molecular difference based on the time when it is harvested. Main living ingredient (just like in every being) of a growing tree is water. Every tree daily transports huge amounts of water. During winter time in the mountains and northern regions there is a term - that wood prepares for a “winter sleep”. The tree grows very slowly in that period. The wood knows that the winter and freeze is coming and that it must leave only a little bit of water inside it’s cells to survive during that period, otherwise it’s cells will explode. Just like when you leave water into the glass bottle to freeze - the bottle will explode and break... In very cold winter nights when the temperature outside drops to -25-35C you can hear in the forest cracking explosive sounds - these are sounds coming especially from the birch trees but from also coniferous trees - where the water in the wood cells freeze to the level it explodes the cells and it cracks.

Our ancestors new the rhythms of nature and knew all about wood more than modern knowledge and science can tell us. By harvesting wood in a cold winter months from December till January they also paid attention to the moon phases - always harvesting trees in the old moon when it is waning. You can do this test by harvesting two trees growing one by another - one in the old and one in the new moon and leave it in the forest from January till www.northmen.com Northmen Guild house builds Quotation July on the ground. One pine tree will have the bark beetle eating it and it will start to mould and have blue stain the other harvested in old moon will still remain fresh and untouched.

Timber harvested by old moon does not contain that much water, sugars and biological ingredients as the water is diamagnetic in liquid form and due to the moon’s electromagnetic connection to the sun and the earth it regulates water amount and consistence in all living organisms. Every old man knows that firewood needs to be cut in the old moon - to get it dried sooner. The same with the wood for construction - logs or timber dry faster (consisting less water), are more stable and they do not need any chemical treatment to protect them from mould and fungal attacks.

In our Northmen house we use timber harvested by old moon in winter time from our forests that are managed by doing only selective cuts (not clear cutting the forests) and we replant twice as more trees than we fell. Wood is a renewable resource. Once Northmen house reaches 100 years mark - all of the trees used in the building will grow back and will be ready for the next house.

Walls

Walls and the roof are over 30 cm thick making this house low in energy consumption. All the beams used in the wall are thick and solid and all the joinery is hand cut mortise and tennon joints locked with white oak pegs. As well as dovetail joints and scarf joints.

2”x4”(two-by-four) modern stick frame nailed prefabricated homes have proven their weakness once faced to the strong wind and natural disasters. Walls must be heavy and solid to be able to call them strong walls. Wall natural construction and insulation in our Northmen home meets passive house standards. House has zero plastic in its construction as the vapour travels through the wall and there is no condensation point even if the outside temperature gets below -30C. Wood in any form does not collect moisture but absorbs it and extracts it. because it is a hygroscopic material, it has a natural tendency to get dry. Only modern insulation materials such as mineral wool, once wet, never gets dry. That’s why it is a rule to wrap such insulated houses in a plastic from inside and live in an unhealthy, non breathing environment which then requires unnatural climate control.

Thick walls and roof are the key for warmth in the winter and the coolness and freshness in the summer as the sun and heat cannot get through the wall from outside. So this house is suitable for all climatic zones - south, Mediterranean and north.

Exterior wooden board cladding - zero maintenance and fireproof

The exterior cladding boards and the porch decking boards are made using pine thermo wood. This is wood that is modified by high heat steam to create a dimensionally stable, rot resistant, chemical free board. No hazardous chemicals are needed to get boards with a higher durability then chemically treated boards. The boards have a brown colour from the heat treatment process and require no additional dyeing except for aesthetics.

Lime plaster

On the walls we will use natural lime plaster. Lime is antibacterial, prevents mould growth and helps to regulate climate indoors and absorbs the light very smooth. It also makes the walls fireproof from inside of the house and works as a vapour membrane itself. The material is more durable then modern plasters due to higher elasticity and is not affected by water.

Should the wall “breath” or no?

Many modern home builders and scientists laugh about when hearing the term “breathable wall” followed by saying that a wall should not breathe - but the ventilation system should ensure air exchange. True - but that is when they talk about houses wrapped in a double or triple layer of plastic. And when the walls have Orientated Strand Boards (OSB, full of synthetic and toxic formaldehyde glues) and foam or mineral insulation. Yes this type of wall does not breathe at all. It is like saying that human being is breathing only through his nose and mouth trying to disprove the fact that we are breathing also trough the skin pores. And what happens if we wrap ourselves with plastic? Or try to live in plastic bag? We will die very soon. The same is with the wood. It is natural material that has pores, small cracks and it is capable to be part of the living environment and making the house a living organism that extracts water condensation and overall regulates the perfect microclimate in our daily life and takes care of our health. Breathable walls help the exchange of this vapour caused by the condensation and in this system the water is fully regulated by the living house.

Windows - modern engineering, traditional design

Until nowadays windows were the main part where all the heat loss of the house goes. By joining modern engineering and natural materials it is possible to build a window without thermal bridges and that works as a solar energy collector in the heating season and in the summer the selective Low E glass coating reflects the sunlight. In our Northmen home project there are 14 or more windows that is a big amount of surface area throughout heat can be lost. Our windows are historic style passive house windows originally engineered in Germany and carefully crafted by our window makers using wood, wood fibre in the window frame and insulated layers of glass reaching the window and frame U value of 0.06 W2MK. The windows have a natural felt membrane made of sheep wool replacing modern plastic membranes.

Roof

Every roofing material is the other key for a lifespan of a natural wooden house and for every house. We use natural slate roof tiles fixed with copper nails. Slate roof lasts a long time and there is no further maintenance needed. Alternative roofing materials are oak shingles or standing seem metal roof plates.

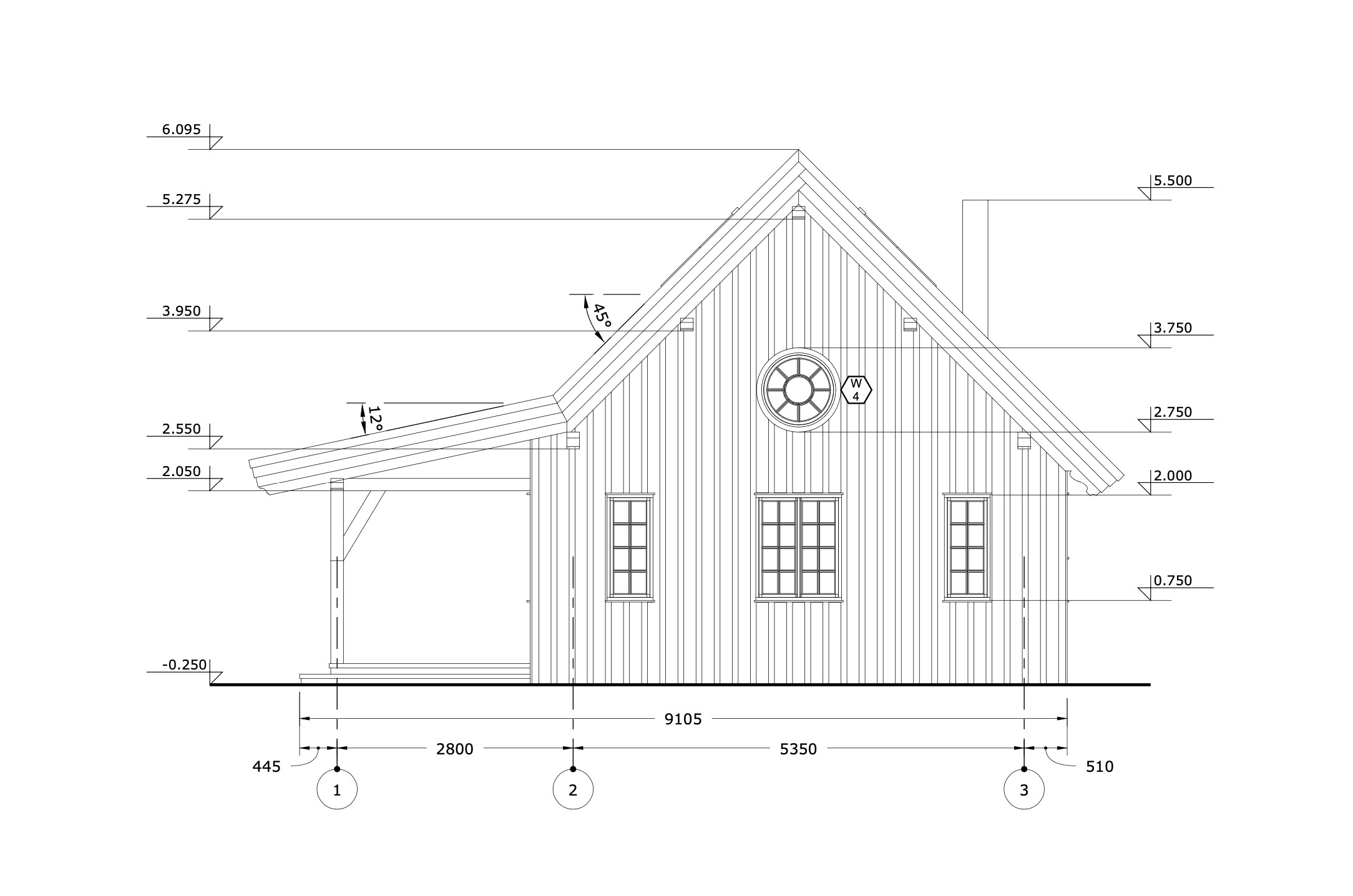

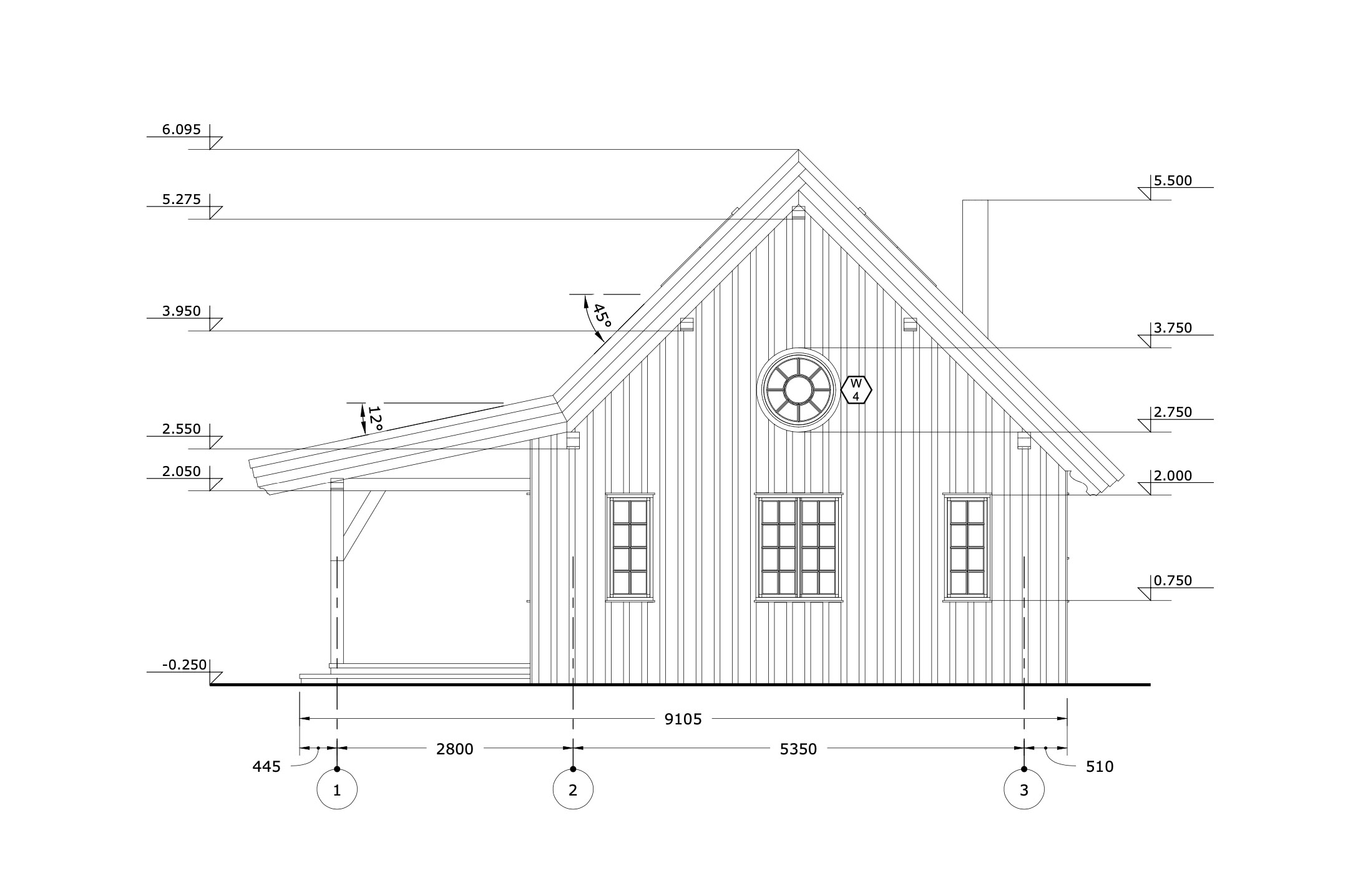

The roof is also the main place where all the heat from the house is lost, by the laws of nature and physics, heat travels upwards. Hence the roof is over 300mm thick that sits on a massive timber frame truss with purlins making this 45 degree roof capable to resist huge snow loads - up to 4 meters (13ft) of snow.

Inquiry form

Get in touch with us for more information about Northmen homes.